A short history of hot dip galvanizing

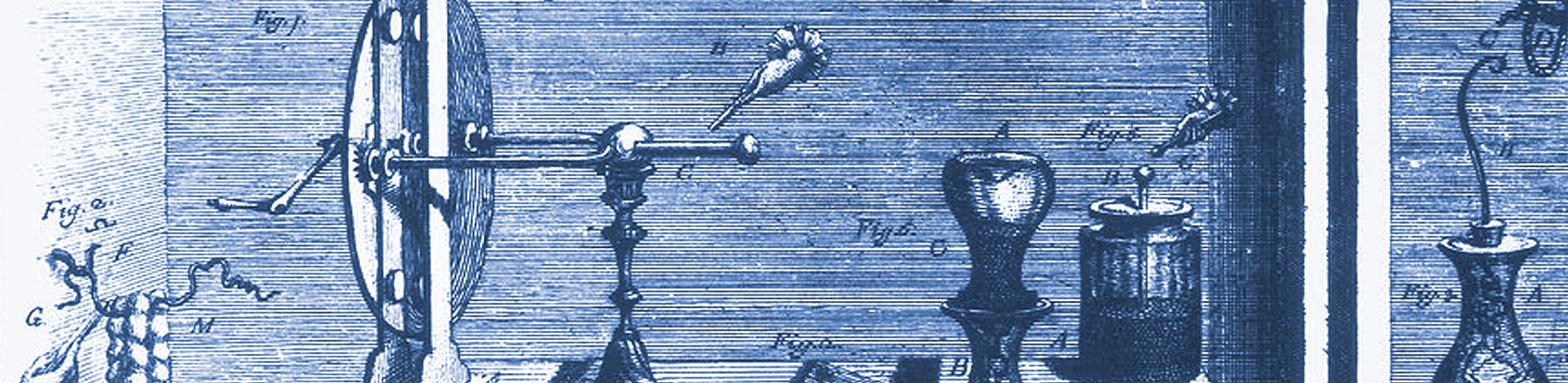

The first (formally acknowledged) step was made by the French chemist Melouin, who, in 1742, submitted to the French Royal Academy a proposal for steel protection, having the metal immersed in a tank filled with molten zinc. In 1836, Sorel, another French chemist, obtained the license for steel protection by means of hot dip galvanizing, after cleansing the metal with a solution made of 9% sulphuric acid. The method was called, at that moment, galvanic paint.

In an article published in 1992 (with the support of the American Galvanizers Association), Charlotte Evans presents a possible history of hot dipping. Her early research directed her to Katherine B. Shippen’s book The Bright Design, which presented the physicist Luigi Galvani, who discovered bioelectricity and called the phenomenon of muscular contraction (which involves a bioelectric stimulus) galvanism, as the inventor of hot dip galvanizing a process he called galvanization.

Other interesting data in the history of zinc are available in the volume edited by H. Mathewson, in the chapter entitled ZINC-the science and technology of metal, alloyages and other elements, written by H.D. Carus (1960). The author talks about the oldest zinc piece discovered, a small statue representing an idol, which was discovered in the sediments of the old settlement of Dordosch (in Transylvania) in pre-historical Dacia. Two ancient zinc bracelets were discovered in the ruins of the settlement of Cameros, destroyed in 500 A.C. the remains of a fountain frontispiece partially covered in zinc was unearthed in Pompeii, destroyed in 79 B.C.

Other interesting data in the history of zinc are available in the volume edited by H. Mathewson, in the chapter entitled ZINC-the science and technology of metal, alloyages and other elements, written by H.D. Carus (1960). The author talks about the oldest zinc piece discovered, a small statue representing an idol, which was discovered in the sediments of the old settlement of Dordosch (in Transylvania) in pre-historical Dacia. Two ancient zinc bracelets were discovered in the ruins of the settlement of Cameros, destroyed in 500 A.C. the remains of a fountain frontispiece partially covered in zinc was unearthed in Pompeii, destroyed in 79 B.C.

In China, zinc was used as early as the 7th century B.C. for coins and mirrors, while in India zinc had been used since 1000 or even 2000 B.C., according to Carus. It is assumed that, around the year 1730, the Chinese technique of processing zinc reached England. Here, in 1740, William Champion of Bristol was the first Englishman who produced and used this metal.

In the United States, zinc was first produced by the Arsenal in Washington D.C. in 1835, with specialists from Belgium.

Charlotte Evans confirms the fact that the first to have discovered and explained hot dip galvanizing (galvanizing) scientifically was P.J. Malouin (not Luigi Galvani), who presented a 20-page report on his experiments to the Royal Science Academy, on August 22 1742, saying: „I believe this work will be considered useful and will shed a new light on the properties and uses of zinc and tin”.

In May 1837, Sorel, a civil engineer, obtained the license for the method of steel protection by immersion in zinc. He called this process galvanizing. In his notes, he writes that he was inspired by Galvani and Volta’s findings, namely that electricity is generated by two different metals, as well as by his own observation, that metals can be preserved by means of oxidation. Sorel assumed, as it was common in that period, that Galvani had played a major part in this process, so he called his own hot dip galvanizing workshop after Galvani, in 1830. Nowadays it is widely accepted that Galvani had always connected electricity with life and that the inventor of the battery had been Volta, not Galvani.

Sorel’s method of covering steel with a layer of zinc consists of cleansing the metal by immersing it first in acid, then in a tank filed with molten zinc. Sorel’s description is partially reproduced below. He later brought 23 improvements to his invention.

Therefore, originally, galvanizing implied only the protection of steel through immersion in zinc. The fact that later procedures, such as hot dip galvanizing or electro-chemical zincing came to be also known as galvanizing is a matter of technological evolution, language or fashion. In the United States, W.T. Flanders, in his book Galvanizing and Tinning, suggested other names for this procedure: hot dip galvanizing, Electro-Zincing, Vapor Zincing, Spray Zincing.

In 1850, England already used 10,000 tons of zinc for steel protection. In 1900, machines specialized in even coverage had already been invented, and aluminium was added to the process, in order to improve the performance of the protective layer.

In 1883, Brooklyn Bridge was inaugurated, being the first suspended bridge which used hot dip galvanizing cables with a total length of 14,568 miles, while in 1965, Rolls Royce used hot dip galvanizing structures for the first time in their factories.